S.I. No. 160/2007 - Legal Metrology (European Conformity Assessment of Measuring Instruments) Regulations 2007.

Notice of the making of this Statutory Instrument was published in | ||||||||||||||||||||||||||||||||||||||||||||||||||||

“Iris Oifigiúil” of 24th April, 2007. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

I, MICHEÁL MARTIN T.D., Minister for Enterprise, Trade and Employment, in exercise of the powers conferred on me by section 3 (1) of the Metrology Act 1996 (No. 27 of 1996), and for the purpose of giving effect to Directive 2004/22/EC of the European Parliament and of the Council of 31 March 2004 on measuring instruments, hereby make the following Regulations— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Part I | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Citation and commencement | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. These Regulations may be cited as the Legal Metrology (European Conformity Assessment of Measuring Instruments) Regulations 2007, and shall come into operation on the making thereof. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Interpretation | ||||||||||||||||||||||||||||||||||||||||||||||||||||

2. In these Regulations— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘Act’ means the Metrology Act 1996 (No. 27 of 1996); | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘authorised officer’ means a person authorised in accordance with Regulation 14; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘authorised representative’ has the same meaning as in Article 4 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘category’, in relation to measuring instruments, means all devices and systems of a kind, or with a measuring function mentioned, in column 1 of the table to Schedule I, and which are subject to the provisions of any one Annex; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘CE marking’ means the marking referred to as such in Regulation 11; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘the Commission’ means the Commission of the European Communities; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘conformity assessment procedures’ means the procedures allowing for conformity assessment made up from the modules described in Annexes A to H1 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘the Directive’ means Directive 2004/22/EC of the European Parliament and of the Council of 31 March 2004 on measuring instruments (OJ L135/1 of 30 April 2004); | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘the Director’ means the Director of Legal Metrology established by section 7 of the Act; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘EEA Member State’ means a State which is a contracting party to the EEA Agreement; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘EEA Agreement’ means the Agreement on the European Economic Area signed in Oporto on 2 May 1992 as adjusted by the protocol signed at Brussels on 17 March 1993; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘essential requirements’ means the requirements set out in Schedule III and in the instrument-specific provisions which apply to a measuring instrument and ‘relevant essential requirements’ means the essential requirements which apply to the measuring instrument concerned; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘harmonised standard’ means a technical specification adopted by the European Committee for Standardisation (CEN), the European Committee for Electrotechnical Standardisation (CENELEC), or the European Telecommunications Standards Institute (ETSI), or jointly by two or all of these organisations, at the request of the Commission pursuant to Directive 98/34/EC of the European Parliament and of the Council of 22 June 1998 (OJ L204/37 of 21 July 1998) laying down a procedure for the provision of information in the field of technical standards and regulations and of rules on Information Society services, as amended by Directive 98/48/EC (OJ L217/18 of 5 August 1998), and prepared in accordance with the General Guidelines agreed among CEN, CENELEC and ETSI and the Commission and the European Free Trade Association and adopted and signed on 28 March 2003 (OJ C91/7 of 16 April 2003); | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘instrument-specific provisions’ means any requirement in the Directive specifically relating to a category of measuring instrument and any requirement in these Regulations, or in any other regulations for the time being in force giving effect to the provisions of the Directive, that relate to a particular category of measuring instrument, and ‘relevant instrument-specific provisions’ means the instrument-specific provisions which apply to the category of measuring instruments concerned; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘Legal Metrology Service’ means the body established under section 7 of the Act; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘measuring instrument’ has the same meaning as in Article 4 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘manufacturer’ has the same meaning as in Article 4 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘Member State’ means an EEA Member State or Switzerland; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘Minister’ means the Minister for Enterprise, Trade and Employment; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘normative document’ means a document containing technical specifications adopted by OIML, subject to the procedure stipulated in Article 16(1) of the Directive, the reference of which is published by the Commission in the Official Journal of the European Communities pursuant to Article 16(1)(b) of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘notified body’ means a body designated by the Minister in accordance with the Directive and these Regulations to carry out tasks pertaining to one or more of the conformity assessment procedures and which has been notified as such to, and received an identification number from, the Commission for such task or tasks and, where the context so admits or requires, includes a body designated in accordance with measures adopted to implement the Directive by an equivalent authority in another Member State, to carry out tasks pertaining to one or more of the conformity assessment procedures and which has been notified as such to, and received an identification number from, the Commission for such task(s); | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘OIML’ means the International Organisation for Legal Metrology (Organisation Internationale de Métrologie Légale) established by the Convention Establishing an International Organisation for Legal Metrology done at Paris on 12 October 1955; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘placing on the market’ has the same meaning as in Article 4 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘prescribed use’ means— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) in the case of a measuring instrument to which these Regulations apply, other than an exhaust gas analyser, use for the purpose of trade (within the meaning of section 2(1) of the Act), and | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) in the case of an exhaust gas analyser, use for the purposes set out in Directive 2005/1955/EC of the European Parliament and of the Council of 28 September 2005 on the approximation of the laws of the Member States relating to the measures to be taken against the emission of gaseous and particulate pollutants from compression-ignition engines for use in vehicles, and the emission of gaseous pollutants from positive-ignition engines fuelled with natural gas or liquefied petroleum gas for use in vehicles (OJ L275/1 of 20 October 2005); | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘putting into use’ has the same meaning as in Article 4 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘relevant national standard’ means a standard implementing a harmonised standard, the reference to which has been published in the Iris Oifigiúil or any procedure in another Member State having equivalent effect to a standard implementing a harmonised standard; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘sub-assembly’ has the same meaning as in Article 4 of the Directive. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Application, derogation and repeal | ||||||||||||||||||||||||||||||||||||||||||||||||||||

3. (1) Subject to paragraphs (2), (3) and (4), Regulation 6 of these Regulations applies to the placing on the market and putting into use in the State of every measuring instrument in each category referred to in column 1 of the table in Schedule I that is intended for a prescribed use. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) By way of derogation from Regulation 6, a measuring instrument referred to in Article 1 of the Directive in respect of which there is for the time being in force a certificate issued or deemed to be issued under the Legal Metrology (Type Approval) Regulations 2006 ( S.I. No. 207 of 2006 ) may be placed on the market or put into a prescribed use until— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the date upon which such certificate (or such certificate as amended, replaced or renewed) expires, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) 30 October 2016, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

whichever is the earlier. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Nothing in these Regulations shall prevent the showing of any measuring instrument of a category referred to in Article 1 of the Directive which does not conform to the requirements of these Regulations at a fair, exhibition, demonstration, or similar event, provided that a visible sign is affixed to, or placed next to such measuring instrument, which sign indicates clearly that the measuring instrument is not available for placing on the market or putting into use until it conforms with these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The provisions of the European Communities (Electromagnetic Compatibility) Regulations 1998 ( S.I. No. 22 of 1998 ) shall not apply to requirements for electromagnetic immunity in respect of any measuring instrument of a category referred to in Article 1 of the Directive and the requirements for electromagnetic immunity specified by the Directive for such measuring instruments shall apply. The provisions of the European Communities (Electromagnetic Compatibility) Regulations 1998 shall be unaffected by these Regulations in so far as those provisions set out requirements in respect of electromagnetic emissions of measuring instruments to which these Regulations or the Directive apply. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) The provisions of paragraphs (1), (2), (3), (4), (5), (6) and (13) of Regulation 4 of the Legal Metrology (Type Approval) Regulations 2006 ( S.I. No. 207 of 2006 ) shall not apply on and from 30 October 2006 to any measuring instrument to which these Regulations apply. For the avoidance of doubt, nothing in this Regulation shall prevent the application of the provisions of paragraphs (7), (8), (9), (10), (11), (12), (14) and (15) of Regulation 4 of the Legal Metrology (Type Approval) Regulations 2006 on and from 30 October 2006 to a type approval given under those Regulations before 30 October 2006 in respect of any measuring instrument to which these Regulations apply, or shall prejudice the validity or effectiveness of any certificate granted or deemed granted under those Regulations before 30 October 2006. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) The provisions of paragraph (5) shall not operate so as to prevent the making and determination of any application under paragraph (12) of the Legal Metrology (Type Approval) Regulations 2006 ( S.I. No. 207 of 2006 ) on or after 30 October 2006. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) Save where inconsistent with the provisions of these Regulations or the Directive, the provisions of the Act and of any regulations (other than these Regulations) made thereunder which relate to control of any instrument (within the meaning of section 2(1) of the Act) which is in service shall apply to a measuring instrument in a category referred to in column 1 of the table in Schedule I (which is not anyway an instrument) as if such measuring instrument were an instrument. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

4. (1) Where instrument-specific provisions lay down essential requirements for sub-assemblies, these Regulations apply to such sub-assemblies as if such sub-assemblies were measuring instruments. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Sub-assemblies and measuring instruments may, at the option of the manufacturer, be assessed together or independently and separately for the purpose of establishing their conformity with the requirements of these Regulations and of any relevant instrument-specific provisions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

5. (1) The enactments referred to in Part A of Schedule II are repealed. Each of the enactments referred to in column 1 of the table in Part B of Schedule II is repealed to the extent indicated in column 2 of that table. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Nothing in the repeals effected by paragraph (1) shall affect the validity of anything done under, or under any power conferred by, any enactment referred to in Schedule II before the repeal of that enactment. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Part II | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Essential requirements and conformity assessment | ||||||||||||||||||||||||||||||||||||||||||||||||||||

6. (1) A measuring instrument in a category referred to in column 1 of the table in Schedule I which is intended for a prescribed use shall meet the essential requirements laid down in Schedule III and those essential requirements identified in column 2 of the table in Schedule I opposite the reference to that category of measuring instruments in column 1 of that table. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The conformity of a measuring instrument referred to in paragraph (1) with the relevant essential requirements referred to in paragraph (1) shall be assessed in accordance with Regulation 7. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) A manufacturer may choose to use any technical solution that complies with the essential requirements referred to in paragraph (1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) In order to benefit from any presumption referred to in Regulation 8, a manufacturer who relies on a relevant national standard or normative document must— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) correctly apply the solutions contained in the relevant national standard(s), or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) correctly apply the solutions contained in the normative document(s) | ||||||||||||||||||||||||||||||||||||||||||||||||||||

which relate to the measuring instrument concerned. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Conformity assessment | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. (1) The conformity assessment of a measuring instrument referred to in Regulation 6(1) with the relevant essential requirements shall be carried out by the application, at the choice of the manufacturer, of one of the conformity assessment procedures in the relevant instrument-specific provisions, (which shall include all of the modules making up any relevant conformity assessment procedure). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Where the conformity assessment procedure requires that the manufacture shall provide, where appropriate, technical documentation for specific measuring instruments, or groups of measuring instruments, that technical documentation shall include the materials and information set out in Schedule IV. If so requested by a notified body, the manufacturer shall provide translations of the technical documentation into the Irish or English language. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Presumption of conformity of relevant national standards and normative documents | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. (1) A measuring instrument referred to in Regulation 6(1) shall be presumed to conform with the essential requirements referred to in Regulation 6(1) if it complies fully with those elements of the relevant national standards or with those elements of the normative documents which correspond to the relevant essential requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Where a measuring instrument referred to in Regulation 6(1) complies only in part with those elements of the relevant national standards or with those elements of the normative documents referred to in paragraph (1), it shall be presumed to conform with the essential requirements referred to in Regulation 6(1) which correspond to the elements of the relevant national standards or the elements of the normative documents with which the measuring instrument complies. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Every notified body referred to in Regulation 12 that meets the criteria laid down in relevant national standards shall be presumed to meet the corresponding criteria specified in Schedule V. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The Minister shall publish the reference to any relevant national standard and the reference to any relevant normative document to which paragraph (1) relates in Iris Oifigiúil. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) It shall be presumed that a measuring instrument referred to in Regulation 6(1) complies with the appropriate tests mentioned in point 3(i) of Schedule IV if the corresponding test programme has been performed in accordance with: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) those elements of the relevant national standards or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) those elements of the normative document(s) | ||||||||||||||||||||||||||||||||||||||||||||||||||||

which correspond to those essential requirements referred to in Regulation 6(1) and if the test results from the test programme undertaken ensure compliance with the essential requirements referred to in Regulation 6(1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Placing on the market and putting into use | ||||||||||||||||||||||||||||||||||||||||||||||||||||

9. (1) Nothing in the Act, any instrument made thereunder or these Regulations shall— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) prohibit or restrict, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) authorise or empower the prohibition or restriction of, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) authorise or empower the refusal to authorise or permit, the placing on the market and/or putting into use of a measuring instrument of a category referred to in Article 1 of the Directive that properly bears the markings referred to in Regulation 10. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Any measuring instrument to which these Regulations apply, that does not meet the requirements specified in these Regulations for the measuring instrument in question, may be seized by or on behalf of the Director and retained by the person seizing it, or may be taken out of use by sealing off the controls of the measuring instrument or by sealing off any premises, vehicle or vessel, or any part of any premises, vehicle or vessel, in which the measuring instrument is found, subject to any direction of any court in that regard. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Marking and identification requirements | ||||||||||||||||||||||||||||||||||||||||||||||||||||

10. (1) Application of the CE marking and the supplementary metrology marking specified in Regulation 11 shall indicate, in the case of prescribed instruments, conformity with Regulation 6(1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Any CE marking and supplementary metrology marking shall be affixed by, or under the responsibility of, the manufacturer. These markings may be affixed to the measuring instrument during the fabrication process, if justified. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Any other marking may be affixed on or to a measuring instrument, provided that the visibility and legibility of the CE marking and the supplementary metrology marking is not thereby reduced, and provided that the affixing of any such marking shall not be likely to deceive third parties as to the meaning and/or form of the CE marking or the supplementary metrology marking. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

11. (1) The CE marking referred to in Regulation 10 consists of the symbol ‘CE’ according to the design laid down in paragraph I.B (d) of the Annex to Council Decision 93/465/EEC (OJ No. L220/23 of 30 August 1993). The CE marking shall be at least 5 millimetres high. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The supplementary metrology marking consists of the capital letter ‘M’ and the last two digits of the year of its affixing, surrounded by a rectangle. The height of the rectangle shall be equal to the height of the CE marking. The supplementary metrology marking shall immediately follow the CE marking. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The identification number of the notified body concerned referred to in Regulation 12, if prescribed by the conformity assessment procedure, shall follow the CE marking and supplementary metrology marking. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) When a measuring instrument consists of a set of devices, not being sub-assemblies, operating together, the markings shall be affixed on the measuring instrument’s main device. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) When a measuring instrument is too small or too sensitive to carry the CE marking and supplementary metrology marking, the markings shall be carried by the packaging, if any, and by the accompanying documents required by the Directive or these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) The ‘CE’ marking and supplementary metrology marking shall be indelible. The identification number of the notified body concerned shall be indelible or self-destructive upon removal. All markings shall be clearly visible or easily accessible. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Notified bodies | ||||||||||||||||||||||||||||||||||||||||||||||||||||

12. (1) A natural or legal person with a place of establishment, or providing services, in the State may be designated by the Minister for the purposes of Article 11 of the Directive as a notified body to perform tasks pertaining to the conformity assessment modules referred to in paragraph (1) of Regulation 7, for any one or more measuring instrument category referred to in Article 1 of the Directive, provided that such person conforms to the requirements set out in Schedule V, and subject to any other limitation contained in any such designation. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) The Minister shall notify the Commission and the other Member States of any designation given under paragraph (1) and shall notify the other Member States of the identification number assigned by the Commission to the notified body concerned in accordance with Article 11(4) of the Directive. Any notification of a designation shall indicate, where relevant, the measuring instrument accuracy classes, the measuring range, the measurement technology and any other instrument characteristic limiting the scope of the notification in respect of the notified body. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Each notified body, save where the said body is the Legal Metrology Service, referred to in Regulation 12(1) shall transmit to the Legal Metrology Service copies (or, as the case may be, written notification) of: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) every EC-type examination and design examination certificate and their annexes, and every addition, amendment and withdrawal relating to every such certificate, issued by it, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) every quality system approval issued, refused or withdrawn by it, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) where requested by the Legal Metrology Service, any evaluation report established by it, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) any other document required of any notified body by the Legal Metrology Service in connection with the performance by the Legal Metrology Service of any responsibility imposed upon it by these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) From time to time, the Minister shall carry out, or arrange to have carried out, an assessment of the performance of every notified body whose designation has been notified in accordance with paragraph (2) to ensure that the notified body continues to meet the criteria set out in Schedule V. A notified body shall produce promptly to the Minister such documents, records and information as the Minister may require for the purpose of any such assessment. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) If, following the assessment carried out in accordance with paragraph (4), the Minister is of the opinion that a notified body no longer conforms to the requirements of Schedule V, the Minister shall, subject to the provisions of these Regulations, revoke the designation given under paragraph (1) and shall withdraw every notification given to the Commission and the other Member States in respect of that notified body. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) The Minister shall not incur any liability for any act or default in the discharge or purported discharge, or performance by a notified body of any of the tasks pertaining to the conformity assessment procedures referred to in paragraph (1) of Regulation 7. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Conformity with directives other than the Directive | ||||||||||||||||||||||||||||||||||||||||||||||||||||

13. (1) Where a measuring instrument is subject to the provisions of any enactment (other than these Regulations) which gives effect to a directive other than the Directive which provisions require the affixing of the CE marking, the marking shall indicate that the measuring instrument in question is also presumed to conform to the requirements of that other directive or those other directives. In such a case, the publication reference of the other directive or directives, in the Official Journal of the European Union, must be given in the documents, notices or instructions required by the provisions of such enactment and accompanying the measuring instrument. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Nothing in these Regulations shall remove any obligation in relation to the marking of any measuring instrument imposed by any enactment other than these Regulations (including any enactment giving effect to a directive other than the Directive). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Part III | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Market surveillance and compliance | ||||||||||||||||||||||||||||||||||||||||||||||||||||

14. (1) For the purpose of ensuring compliance with these Regulations and carrying out market surveillance required by Article 18 of the Directive, the Director may— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) appoint any person for the time being assigned to or working in the Legal Metrology Service or any person for the time being appointed an inspector under section 9 of the Act to be an authorised officer for the purposes of these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) subject to paragraph (4), require any authorised officer to perform such tasks relating to these Regulations or to market surveillance specified by the Director for any category or categories of measuring instrument either exclusively, or in conjunction with any other duties performed by that person. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Every person appointed under paragraph (1) to be an authorised officer shall be furnished with a certificate by the Director of his or her appointment. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The Director may, at any time, revoke an appointment under paragraph (1), and, in such case, the person whose appointment is so revoked shall promptly surrender to the Director the certificate furnished under paragraph (2). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The Director shall not require any authorised officer to carry out tasks relating to market surveillance for any category or categories of measuring instrument where, in the opinion of the Director, there would be a risk, or a substantial risk of, a conflict between such requirement and the performance of the other duties of that person, including without limitation, duties relating to any activity undertaken by a notified body. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Market surveillance shall be carried out for the purpose of ensuring that measuring instruments that breach any requirement of these Regulations are neither placed on the market nor put into use. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) For the purpose of carrying out tasks relating to market surveillance, an authorised officer may, or may be required by the Director, subject to the production, if so required, of his or her certificate of appointment, to— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) at all reasonable times, visit any premises or place including a vehicle or vessel, where, in the opinion of the Director or the authorised officer, measuring instruments are, or are likely, to be found; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) at all reasonable times, enter any premises or place, including a vehicle or vessel in which he or she reasonably believes there are, or are likely to be, for the time being any measuring instruments; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) on entering any premises or place by virtue of this Regulation, be accompanied by any such other persons and take with him or her any such equipment as may appear to be necessary; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(d) inspect such premises or place and examine or test any measuring instrument to satisfy himself as to its conformity or otherwise with the requirements of these Regulations or the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(e) conduct any examination or testing which the Director considers necessary or desirable for the purpose of assisting a competent authority of another Member State to fulfil its obligations in accordance with Article 18 of the Directive; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(f) take away for examination and testing any such measuring instrument, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(g) report to the Director, as soon as possible, on the result of any examination or testing of any measuring instrument or on the results of such examinations or testing generally; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(h) require the owner, person in charge or any employee of any premises or place entered, or any other person who appears to him or her to be in control of any measuring instrument, to provide him or her with such information or assistance as he or she considers necessary (including personal assistance, access to books, documents or other records, including any records kept on any computer, or other electronic means of storage or retrieval) to enable him or her to establish whether any device or thing is a measuring instrument, to examine or test any measuring instrument, or to carry out any other function under these Regulations; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) inspect and copy or take extracts from any such books, documents or records, including, in the case of such records in a non-legible form, a copy of, or an extract from, such records in a permanent legible form; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(j) in the case of any vehicle or vessel, request the owner or operator thereof to bring the vehicle or vessel to the nearest location at which appropriate test facilities are available and at which an examination or test may be carried out. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) When exercising any powers conferred on him or her by section 10 of the Act, an inspector who is an authorised officer may exercise any power conferred on him or her by these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) When exercising any powers conferred on him or her by these Regulations, an authorised officer who is an inspector may exercise any power conferred on him or her by section 10 of the Act. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(9) An authorised officer who takes away a measuring instrument pursuant to paragraph (6) shall notify forthwith, and issue a receipt to, the person on whose premises the measuring instrument is taken, or that person’s authorised representative, indicating that the measuring instrument is taken in pursuance of these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(10) An authorised officer may seize and retain— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) any article, measuring instrument, stamp or other thing which he or she reasonably believes to be in contravention of these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) any such books, documents or records referred to in paragraph (6)(h) of this Regulation which the authorised officer reasonably believes may be required as evidence in any proceedings. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(11) An authorised officer may, if the Director considers it necessary, be accompanied by a member of An Garda Síochána when exercising any powers conferred on an authorised officer by these Regulations. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Where non-compliance suspected | ||||||||||||||||||||||||||||||||||||||||||||||||||||

15. (1) Where an authorised officer suspects that it is probable that all or part of each of two or more measuring instruments of the same category and a particular model bearing the markings referred to in Regulation 11 do not meet the essential requirements relating to metrological performance imposed by these Regulations on a measuring instrument intended for a prescribed use or set out in the Directive for measuring instruments that are not referred to in column 1 of the table in Schedule 1, when correctly installed and used in accordance with the manufacturer’s instructions, he or she shall notify the Director. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Where an authorised officer suspects that the CE marking or the supplementary metrology marking has been affixed unduly on or to a measuring instrument he or she shall notify the Director. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The Director shall request the manufacturer or the manufacturer’s authorised representative to make submissions to him or her on any notification made to him or her under paragraph (1) or paragraph (2), and may invite any other person or body (including any notified body) that he considers may have an interest in the matter to make submissions to him. In considering each such notification, the Director shall have regard to any report provided by the authorised officer and to any other information or documents which the Director considers relevant, and may consult with any person or body whom he or she considers appropriate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The Director shall consider every notification made to him or her under paragraph (1) for the purpose of forming an opinion on whether all or part of the measuring instruments of the category and model concerned bearing the markings referred to in Regulation 11 do not meet the essential requirements imposed by these Regulations or set out in the Directive as applicable, when correctly installed and used in accordance with the manufacturer’s instructions. The Director shall, in considering such notification, have regard to whether it appears such non-compliance (if found) is systematic or incidental. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Where the Director forms the opinion that all or part of the measuring instruments of the category and model concerned in a notification under paragraph (1) bearing the markings referred to in Regulation 11 do not meet the essential requirements relating to metrological performance imposed by these Regulations or set out in the Directive as applicable, when correctly installed and used in accordance with the manufacturer’s instructions, he or she shall: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

provide a report to the Minister which sets out his or her opinion, and which also includes: (a) a statement of the exact grounds upon which that opinion was formed, (b) an opinion as to whether such non-compliance is systematic or incidental and the exact grounds upon which that opinion was formed and (c) a recommendation as to the action to be taken by the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

The Director shall provide a copy of such report to the manufacturer of the measuring instrument or the manufacturer’s authorised representative. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) If, following consideration of a notification under paragraph (2), and having considered the submissions, if any, made to him or her, the Director is of the opinion that the CE marking or the supplementary metrology marking has been affixed unduly to the measuring instrument concerned, he or she may, subject to the provisions of these Regulations, by direction in writing given to the manufacturer of the measuring instrument or the manufacturer’s authorised representative: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) require that person to make the measuring instrument concerned conform as regards those provisions concerning the CE marking or supplementary metrology marking not covered by Article 19(1) of the Directive; and/or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) require that person to end any infringement of any relevant provisions within such period and subject to such conditions as are specified in the direction, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

and that person shall comply with the direction. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) Where in the opinion of the Director, a person has persisted in failing to comply with a direction given under paragraph (6), the Director shall provide a report to the Minister which sets out his or her opinion, and which also includes: (a) a statement of the exact grounds upon which that opinion was formed, and (b) a recommendation as to the action to be taken by the Minister. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(8) A person aggrieved by a direction given to him, her or it under paragraph (6) may appeal that direction to the Minister pursuant to the procedure prescribed in Regulation 20 by notice of appeal in writing sent to the Minister and copied to the Director within fourteen days of the giving to that person of notice of the direction. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(9) The Director may withdraw a direction given by him or her under paragraph (6). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Reference of non-compliance to Minister | ||||||||||||||||||||||||||||||||||||||||||||||||||||

16. (1) Where the Director has provided the Minister with a report in accordance with paragraph (5) of Regulation 15 or paragraph (7) of Regulation 15, and the Minister, having considered the Director’s report and any information, documents or submissions he or she considers appropriate, agrees with the opinion of the Director: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the Minister may, by direction in writing, containing a statement of the exact grounds upon which such direction is given, transmitted to the person who is placing or has placed the measuring instruments concerned on the market or who is putting or has put the measuring instruments concerned into use- | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) prohibit that person from placing or continuing to place on the market, or from putting or continuing to put into use, the measuring instruments concerned, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) impose on that person such restrictions as he considers appropriate on his, her or its placing or continuing to place on the market or from putting into use the measuring instruments concerned, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) require that person to take specified steps to withdraw from the market or from use, as the case may be, any measuring instruments concerned already placed by him, her or it on the market or in use, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

and that person shall comply with the direction, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the Minister may request any notified body referred to in Regulation 12(1) to review any certificate, approval or report issued by such notified body in connection with any matter to which such direction relates, within a period specified by the Minister, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) the Minister may provide a copy of the direction (and any other information or document he or she considers appropriate in the circumstances) to any competent authority or notified body of any Member State. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Any direction given under paragraph (1) shall state whether the non-compliance to which the direction relates is systematic or incidental. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Where the Minister gives a direction under paragraph (1), which contains a statement that states the non-compliance to which the direction relates is systematic, he or she shall immediately inform the Commission and provide the Commission with a copy of the direction, which includes the exact grounds upon which the direction is given. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) A person aggrieved by a direction given to him, her or it under paragraph (1) may appeal that direction to the Minister pursuant to the procedure prescribed in Regulation 20 by notice of appeal in writing sent to the Minister within fourteen days of the giving to that person of notice of the direction. Any direction given under paragraph (1) shall contain a statement to that effect. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) The requirement to comply with any direction given by the Minister under paragraph (1) which contains a statement that the non-compliance to which the direction relates is systematic may be suspended by the Minister pending receipt of the Commission’s findings in accordance with Article 19(2) of the Directive. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) The Minister may withdraw a direction given by him or her under paragraph (1). | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) When the Commission has issued its findings in accordance with Article 19 of the Directive in connection with any matter of which he or she has informed the Commission under this Regulation, the Minister shall take such steps as are appropriate having regard to such findings pursuant to his or her powers under these Regulations or under the Act. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Non-compliance with directions | ||||||||||||||||||||||||||||||||||||||||||||||||||||

17. (1) Where a person fails to comply with a direction given under Regulation 16, the Minister may— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) apply summarily to the High Court for such orders as are necessary or appropriate to give full effect to the direction, and | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) take such other action, as he or she considers appropriate to restrict or prohibit the placing on the market of the measuring instrument in question or to ensure that it is withdrawn from the market or that its further use is restricted or prohibited. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Administrative co-operation | ||||||||||||||||||||||||||||||||||||||||||||||||||||

18 (1) The Legal Metrology Service shall be the competent authority in the State responsible for the functions identified in Article 18(2) and Article 18(3) of the Directive, and such functions shall be performed by the Director, who may require any person for the time being assigned to or working in the Legal Metrology Service to perform any tasks relating to such functions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Without prejudice to the generality of paragraph (1), the Legal Metrology Service shall— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) so far as is reasonably practicable, assist the competent authority (for the purposes of the Directive) of any other Member State when so requested in the fulfilment of that competent authority’s obligations to carry out market surveillance, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) provide to the competent authorities (for the purposes of the Directive) of the other Member States at such intervals, as it considers appropriate— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(i) information concerning the extent to which measuring instruments examined by authorised officers comply with the provisions of the Directive, and the results of such examinations; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(ii) copies of any EC type-examination and design-examination certificates and their annexes issued by every notified body referred to in Regulation 12(1), and any additions or amendments to, or withdrawals of, any such certificates; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(iii) any quality system approvals issued by any notified body referred to in Regulation 12(1), and information on any quality systems refused such approval or in respect of which approval is withdrawn; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(iv) any evaluation report established by any notified body referred to in Regulation 12(1), when such report is demanded by the competent authority (within the meaning of the Directive) of any other Member State; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) make available to each notified body referred to in Regulation 12(1) such information relating to EC type-examination and design-examination certificates and quality system approvals, as it considers necessary. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Procedure where adverse decision proposed | ||||||||||||||||||||||||||||||||||||||||||||||||||||

19 (1) Where— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) the Minister intends to revoke a designation in accordance with Regulation 12(5) or to issue a direction in accordance with Regulation 16(1), or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) the Director intends to issue a direction in accordance with Regulation 15(6), | ||||||||||||||||||||||||||||||||||||||||||||||||||||

he or she shall in such case inform the person or body who would be the addressee of such revocation or direction of that intention and the reasons therefor and shall afford the person or body concerned a period of not less than twenty-one days to make further submissions or representations to him or her on the intended revocation or direction. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Appeal procedure | ||||||||||||||||||||||||||||||||||||||||||||||||||||

20. Where a person appeals a direction of the Director under Regulation 15(8), or appeals a direction of the Minister under Regulation 16(4) the procedure on such appeal shall be as follows— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(1) Any decision taken resulting in a restriction being imposed on the placing on the market or putting into service of an instrument shall be notified to the person concerned, stating the exact grounds for the decision and confirming the right to appeal against the decision under paragraph (2) and the time limit for bringing such an appeal. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Any person aggrieved by a decision under paragraph (1) may, by notice in writing given to the Minister not later than 14 days after receipt by that person of notice of that decision, appeal to the Minister against the decision and the Minister, having considered any submission made to him or her by the person and any other interested parties and the report of any inquiry held under paragraph (3) in relation to the appeal or of any assessor appointed under paragraph (4) in relation thereto, may uphold, vary or reverse the decision under appeal. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) The Minister may appoint an officer to hold an inquiry in connection with an appeal under this Regulation and to report to the Minister on the findings and result of the inquiry. Such officer shall not have had any involvement in the preparation of the decision under appeal or in advising the Minister in respect of same. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) The Minister may appoint an assessor to assist him or her and to make a report to him or her in relation to an appeal under this Regulation or to assist an officer of the Minister in relation to an inquiry being held by the Minister under paragraph (2). An assessor shall not have had any involvement in the preparation of the decision under appeal or in advising the Minister in respect of same. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) A copy of the recommendations of any report submitted to the Minister pursuant to paragraphs (3) or (4) shall, on request, be made available to the person who has brought the appeal before the Minister and the Minister shall consider any submission made by that person in respect of such recommendations provided any such submission is submitted within a period to be fixed by the Minister on a case-by-case basis, which shall not be less that 14 days after the notification of the recommendation to the person concerned. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Any person aggrieved by a decision of the Minister under these Regulations may appeal to the High Court against the decision and the court may vary, annul or confirm the decision. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Offences | ||||||||||||||||||||||||||||||||||||||||||||||||||||

21. (1) Any person who places on the market or causes to be placed on the market (including, for the avoidance of doubt, any person who causes to be offered for sale, whether by lease, rental or other type of agreement), or puts into use or causes to be put into use, any measuring instrument to which Regulation 6(1) applies, that does not meet the requirements specified in the said Regulation 6(1) for the measuring instrument in question, shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Any person who places on the market or causes to be placed on the market (including, for the avoidance of doubt, any person who causes to be offered for sale, whether by lease, rental or other type of agreement), or puts into use or causes to be put into use, any measuring instrument to which Regulation 6(1) applies, that does not bear the markings referred to in Regulation 10(1), shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Any person who purports to affix or causes to be affixed the CE marking or the supplementary metrology marking to a measuring instrument that does not comply with the requirements of these Regulations or the Directive, as applicable, shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Any person who affixes a marking on or to a measuring instrument that is likely to deceive a third party as to the meaning and/or form of the CE marking, or the supplementary metrology, marking shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Any person who affixes a CE marking in contravention of Regulation 10 shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) A person who— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) obstructs or impedes an authorised officer in the exercise of his or her powers conferred by these Regulations, or does not comply with a requirement made by an authorised officer exercising powers conferred by these Regulations, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) fails, without reasonable cause, to give an authorised officer any such assistance or information which the authorised officer may reasonably require for the purpose of the exercise by the authorised officer of his or her powers under these Regulations, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) knowingly or recklessly makes a false or misleading statement, either verbally or in writing, to an authorised officer who is exercising his or her powers conferred by these Regulations, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) Where a person fails to comply with a direction given under Regulation 16, for the time being in force, he or she shall be guilty of an offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Prosecution and penalties | ||||||||||||||||||||||||||||||||||||||||||||||||||||

22. (1) A person guilty of an offence under these Regulations shall be liable, on summary conviction, to a fine not exceeding €3,000 or in the case of an individual, to imprisonment for a term not exceeding twelve months or to both such fine and such imprisonment. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(2) Any Court which has tried an offence under these Regulations may, at the conclusion of such trial, give such directions and make such orders as appear to it appropriate in respect of any measuring instrument to which such trial relates, which may include— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) orders for the forfeiture and/or disposal of that measuring instrument; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) orders directing the affixing of marking to, or the obliteration of markings from, that measuring instrument; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(c) orders directing the person controlling that measuring instrument to take steps specified by the court in relation to that measuring instrument. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(3) Where the commission by any person of an offence under these Regulations, is due to the act or default of some other person, that other person shall also be guilty of the offence and may be charged with and convicted of the offence, whether or not proceedings are taken against the first-mentioned person. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(4) Where an offence, committed by a body corporate, is proved to have been committed with the consent or connivance of, or to be attributable to any neglect on the part of, any director, manager, secretary or other similar officer of the body corporate or any person purporting to act in any such capacity, that person, as well as the body corporate, shall be guilty of the offence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(5) Where the affairs of a body corporate are managed by its members, paragraph (4) shall apply in relation to the acts and defaults of a member or an officer of the body in question in connection with responsibilities or functions of management conferred on him or her. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(6) Notwithstanding section 10(4) of the Petty Sessions (Ireland) Act 1851, proceedings for an offence under these Regulations may be instituted at any time: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(a) within one year from the date on which the offence was committed, or | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) at any time within 6 months from the date on which evidence sufficient in the opinion of the Director to justify initiating the proceedings, comes to the Director’s knowledge, not being later than 5 years from the date on which the offence concerned was committed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(7) Summary proceedings for an offence under these Regulations may be brought and prosecuted by the Director. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Further provision | ||||||||||||||||||||||||||||||||||||||||||||||||||||

23. Where any measuring instrument is seized and detained under these Regulations, any person aggrieved by such seizure and detention may appeal to a Judge of the District Court under this Regulation as if section 30 of the Act applied to a seizure and detention under these Regulations as it applies to a seizure and detention under section 10(4) of the Act. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE I | ||||||||||||||||||||||||||||||||||||||||||||||||||||

MEASURING INSTRUMENT CATEGORIES AND INSTRUMENT-SPECIFIC ESSENTIAL REQUIREMENTS | ||||||||||||||||||||||||||||||||||||||||||||||||||||

TABLE | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE II | ||||||||||||||||||||||||||||||||||||||||||||||||||||

REPEALS | ||||||||||||||||||||||||||||||||||||||||||||||||||||

PART A COMPLETE REPEAL | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

PART B Partial Repeal | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

SCHEDULE III | ||||||||||||||||||||||||||||||||||||||||||||||||||||

ESSENTIAL REQUIREMENTS | ||||||||||||||||||||||||||||||||||||||||||||||||||||

A measuring instrument shall provide a high level of metrological protection in order that any party affected can have confidence in the result of measurement, and shall be designed and manufactured to a high level of quality in respect of the measurement technology and security of the measurement data. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

The requirements that shall be met by measuring instruments are set out below and are supplemented, where appropriate, by specific instrument requirements listed in Schedule I that provide more detail on certain aspects of the general requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

The solutions adopted in the pursuit of the requirements shall take account of the intended use of the instrument and any foreseeable misuse thereof. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Definitions | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘climatic environments’ mean the conditions in which measuring instruments may be used. To cope with climatic differences between the Member States, a range of temperature limits has been defined. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘critical change value’ means the value at which the change in the measurement result is considered undesirable; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

a trading transaction is ‘direct sales’ if: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— the measurement result serves as the basis for the price to pay and; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— at least one of the parties involved in the transaction related to measurement is a consumer or any other party requiring a similar level of protection and; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— all the parties in the transaction accept the measurement result at that time and place. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘disturbance’ means an influence quantity having a value within the limits specified in the appropriate requirement but outside the specified rated operating conditions of the measuring instrument. An influence quantity is a disturbance if for that influence quantity the rated operating conditions are not specified; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘measurand’ means the particular quantity subject to measurement; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘influence quantity’ means a quantity that is not the measurand but that affects the result of measurement; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘material measure’ means a device intended to reproduce or supply in a permanent manner during its use one or more known values of a given quantity; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘rated operating conditions’ means the values for the measurand and influence quantities making up the normal working conditions of a measuring instrument; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

‘utility’ is regarded as a supplier of electricity, gas, heat or water. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Requirements | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Allowable Errors | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 1. Under rated operating conditions and in the absence of a disturbance, the error of measurement shall not exceed the maximum permissible error (MPE) value as laid down in the appropriate instrument-specific requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Unless stated otherwise in the instrument-specific requirements, MPE is expressed as a bilateral value of the deviation from the true measurement value. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 2. Under rated operating conditions and in the presence of a disturbance, the performance requirement shall be as laid down in the appropriate instrument-specific requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Where the measuring instrument is intended to be used in a specified permanent continuous electromagnetic field the permitted performance during the radiated electromagnetic field amplitude modulated test shall be within MPE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 3. The manufacturer shall specify the climatic, mechanical and electromagnetic environments in which the measuring instrument is intended to be used, power supply and other influence quantities likely to affect its accuracy, taking account of the requirements laid down in the appropriate instrument-specific requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 3.1. Climatic environments | ||||||||||||||||||||||||||||||||||||||||||||||||||||

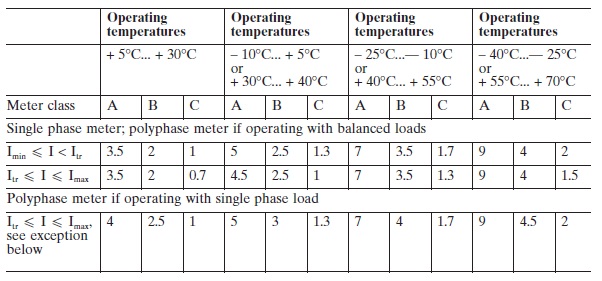

The manufacturer shall specify the upper temperature limit and the lower temperature limit from any of the values in Table 1 unless otherwise specified in the instrument-specific requirements, and indicate whether the measuring instrument is designed for condensing or non-condensing humidity as well as the intended location for the measuring instrument, i.e. open or closed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 3.2. (a) Mechanical environments are classified into classes M1 to M3 as described below. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

M1 This class applies to measuring instruments used in locations with vibration and shocks of low significance, e.g. for measuring instruments fastened to light supporting structures subject to negligible vibrations and shocks transmitted from local blasting or pile driving activities, slamming doors, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 This class applies to measuring instruments used in locations with significant or high levels of vibration and shock, e.g. transmitted from machines and passing vehicles in the vicinity or adjacent to heavy machines, conveyor belts, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

M3 This class applies to measuring instruments used in locations where the level of vibration and shock is high and very high, e.g. for measuring instruments mounted directly on machines, conveyor belts, etc. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) The following influence quantities shall be considered in relation with mechanical environments: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

– Vibration; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

– Mechanical shock. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 3.3. (a) Electromagnetic environments are classified into classes E1, E2 or E3 as described below, unless otherwise laid down in the appropriate instrument-specific requirements. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

E1 This class applies to measuring instruments used in locations with electromagnetic disturbances corresponding to those likely to be found in residential, commercial and light industrial buildings. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

E2 This class applies to measuring instruments used in locations with electromagnetic disturbances corresponding to those likely to be found in other industrial buildings. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

E3 This class applies to measuring instruments supplied by the battery of a vehicle. Such measuring instruments shall comply with the requirements of E2 and the following additional requirements: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— voltage reductions caused by energising the starter-motor circuits of internal combustion engines | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— load dump transients occurring in the event of a discharged battery being disconnected while the engine is running. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

(b) The following influence quantities shall be considered in relation with electromagnetic environments: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Voltage interruptions, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Short voltage reductions, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Voltage transients on supply lines and/or signal lines, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Electrostatic discharges, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Radio frequency electromagnetic fields, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Conducted radio frequency electromagnetic fields on supply lines and/or signal lines, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Surges on supply lines and/or signal lines. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 3.4. Other influence quantities to be considered, where appropriate, are: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Voltage variation, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Mains frequency variation, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— Power frequency magnetic fields, | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— any other quantity likely to influence in a significant way the accuracy of the measuring instrument. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 4. When carrying out the tests as envisaged in these Regulations, the following paragraphs apply: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 4.1. Basic rules for testing and the determination of errors | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Essential requirements specified in 1.1 and 1.2 shall be verified for each relevant influence quantity. Unless otherwise specified in the appropriate instrument-specific requirements, these essential requirements apply when each influence quantity is applied and its effect evaluated separately, all other influence quantities being kept relatively constant at their reference value. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Metrological tests shall be carried out during or after the application of the influence quantity, whichever condition corresponds to the normal operational status of the measuring instrument when that influence quantity is likely to occur. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

1. 4.2. Ambient humidity | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— According to the climatic operating environment in which the measuring instrument is intended to be used either the damp heat steady state (non-condensing) or damp heat cyclic (condensing) test may be appropriate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— The damp heat cyclic test is appropriate where condensation is important or when penetration of vapour will be accelerated by the effect of breathing. In conditions where non-condensing humidity is a factor the damp heat steady state is appropriate. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

2. Reproducibility | ||||||||||||||||||||||||||||||||||||||||||||||||||||

The application of the same measurand in a different location or by a different user, all other conditions being the same, shall result in the close agreement of successive measurements. The difference between the measurement results shall be small when compared with the MPE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

3. Repeatability | ||||||||||||||||||||||||||||||||||||||||||||||||||||

The application of the same measurand under the same conditions of measurement shall result in the close agreement of successive measurements. The difference between the measurement results shall be small when compared with the MPE. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

4. Discrimination and Sensitivity | ||||||||||||||||||||||||||||||||||||||||||||||||||||

A measuring instrument shall be sufficiently sensitive and the discrimination threshold shall be sufficiently low for the intended measurement task. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

5. Durability | ||||||||||||||||||||||||||||||||||||||||||||||||||||

A measuring instrument shall be designed to maintain an adequate stability of its metrological characteristics over a period of time estimated by the manufacturer, provided that it is properly installed, maintained and used according to the manufacturer’s instruction when in the environmental conditions for which it is intended. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

6. Reliability | ||||||||||||||||||||||||||||||||||||||||||||||||||||

A measuring instrument shall be designed to reduce as far as possible the effect of a defect that would lead to an inaccurate measurement result, unless the presence of such a defect is obvious. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. Suitability | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. 1. A measuring instrument shall have no feature likely to facilitate fraudulent use, whereas possibilities for unintentional misuse shall be minimal. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. 2. A measuring instrument shall be suitable for its intended use taking account of the practical working conditions and shall not require unreasonable demands of the user in order to obtain a correct measurement result. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. 3. The errors of a utility measuring instrument at flows or currents outside the controlled range shall not be unduly biased. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. 4. Where a measuring instrument is designed for the measurement of values of the measurand that are constant over time, the measuring instrument shall be insensitive to small fluctuations of the value of the measurand, or shall take appropriate action. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. 5. A measuring instrument shall be robust and its materials of construction shall be suitable for the conditions in which it is intended to be used. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

7. 6. A measuring instrument shall be designed so as to allow the control of the measuring tasks after the instrument has been placed on the market and put into use. If necessary, special equipment or software for this control shall be part of the measuring instrument. The test procedure shall be described in the operation manual. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

When a measuring instrument has associated software which provides other functions besides the measuring function, the software that is critical for the metrological characteristics shall be identifiable and shall not be inadmissibly influenced by the associated software. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. Protection against corruption | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. 1. The metrological characteristics of a measuring instrument shall not be influenced in any inadmissible way by the connection to it of another device, by any feature of the connected device itself or by any remote device that communicates with the measuring instrument. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. 2. A hardware component that is critical for metrological characteristics shall be designed so that it can be secured. Security measures foreseen shall provide for evidence of an intervention. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. 3. Software that is critical for metrological characteristics shall be identified as such and shall be secured. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Software identification shall be easily provided by the measuring instrument. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Evidence of an intervention shall be available for a reasonable period of time. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. 4. Measurement data, software that is critical for measurement characteristics and metrologically important parameters stored or transmitted shall be adequately protected against accidental or intentional corruption. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

8. 5. For utility measuring instruments the display of the total quantity supplied or the displays from which the total quantity supplied can be derived, whole or partial reference to which is the basis for payment, shall not be able to be reset during use. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

9. Information to be borne by and to accompany the measuring instrument | ||||||||||||||||||||||||||||||||||||||||||||||||||||

9. 1. A measuring instrument shall bear the following inscriptions— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— manufacturer’s mark or name; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— information in respect of its accuracy; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

plus, when applicable— | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— information in respect of the conditions of use; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— measuring capacity; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— measuring range; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— identity marking; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— number of the EC type examination certificate or the EC design examination certificate; | ||||||||||||||||||||||||||||||||||||||||||||||||||||

— information whether or not additional devices providing metrological results comply with the provisions of the Directive on legal metrological control. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

9. 2. A measuring instrument of dimensions too small or of too sensitive a composition to allow it to bear the relevant information shall have its packaging, if any, and the accompanying documents required by the provisions of the Directive suitably marked. | ||||||||||||||||||||||||||||||||||||||||||||||||||||

9. 3. The measuring instrument shall be accompanied by information on its operation, unless the simplicity of the measuring instrument makes this unnecessary. Information shall be easily understandable and shall include where relevant: | ||||||||||||||||||||||||||||||||||||||||||||||||||||